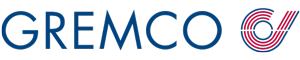

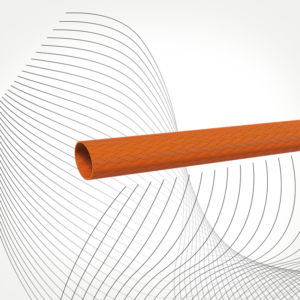

FITCOFLEX® BRAIDED TUBING

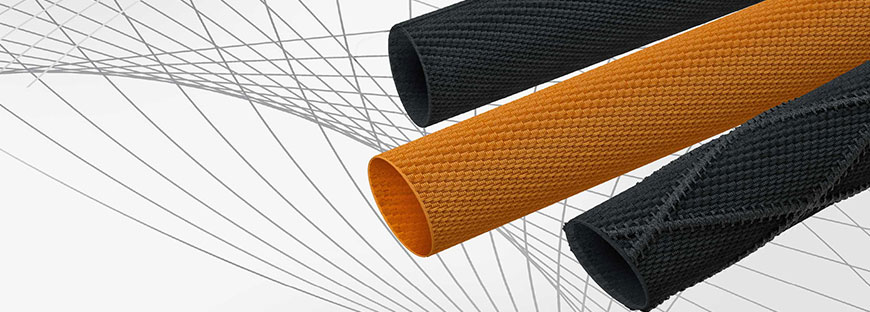

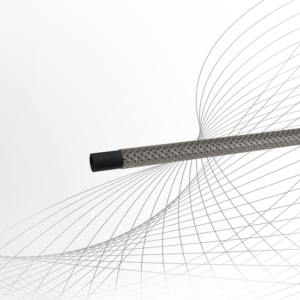

Our FITCOFLEX® braided sleeving is a monofilament-based braided hose and is used to protect cables, wires, hoses, and pipes from extreme mechanical and thermal stresses. Braided sleeves are highly flexible, allowing them to adapt easily to components, and are available in a variety of materials as well as different degrees of surface coverage. Installation is uncomplicated and fast, for example, to protect against mechanical wear, but also finds applications for cable bundling or as rattle protection.

The special feature is that the lightweight and high flexibility of our FITCOFLEX® cable protection qualifies it for a wide range of industrial applications. The material properties optimized by GREMCO are particularly suitable for use in the aerospace and automotive industries, as well as in medical and environmental technology.

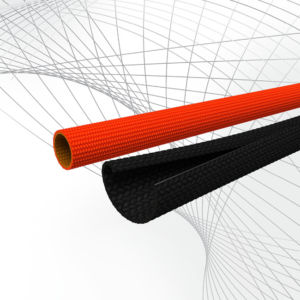

Braided tubing variants for optimum protection of wires and cables

FITCOFLEX® braided tubing is versatile and always ensures first-class preservation of its contents. We offer three different braided sleeving variants: Expandable or self-coiling FITCOFLEX®, and hoses as noise insulation.

You are unsure which variant is the best option for your industrial application? As a long-standing braided sleeving manufacturer, our trained sales team will expertly assist you in finding your optimal system solution. Contact us!