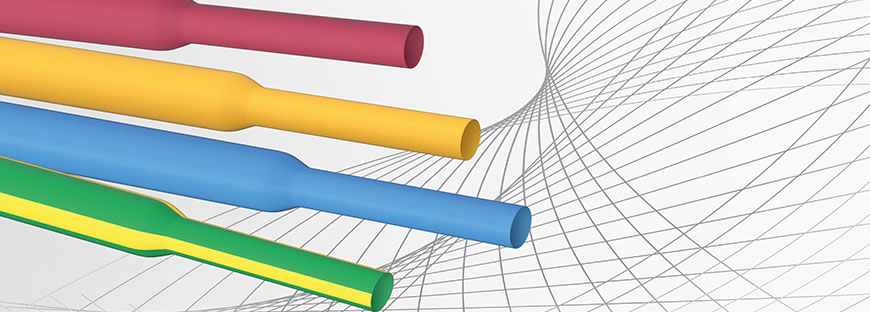

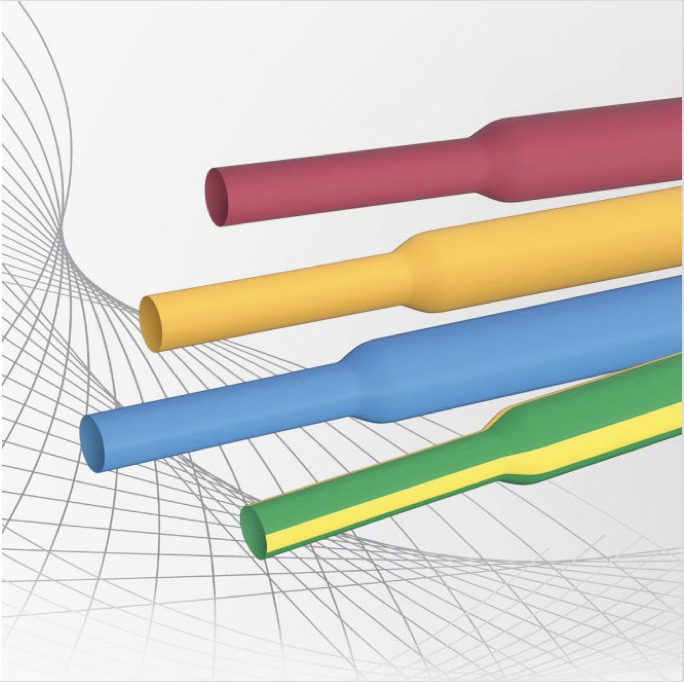

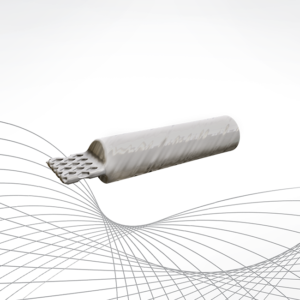

HEAT-SHRINK TUBING – FITCOTUBE®

FITCOTUBE® heat-shrink tubing has a high level of resistance with a consistently high surface quality. They effectively protect wires and cables from mechanical, thermal and chemical influences.

Our heat-shrink tubing is available in different versions and also with international approvals and specifications, e.g. MIL or UL approval. They are especially suitable for the requirements of the automotive, environmental, medical and aviation industries.

FITCOTUBE® heat-shrink tubing is constantly being developed in close cooperation with heat-shrink tubing manufacturer GREMCO’s customers from a wide variety of industries and, therefore, can always be implemented individually. Moreover, we offer application-oriented developments in all areas.

Our heat-shrink tubing for optimal protection of wires and cables

The GREMCO FITCOTUBE® is available in different types, utilizing different materials to meet the extensively varying application requirements. The heat shrink products can also be customized, e.g. by optional lengths or imprinting.